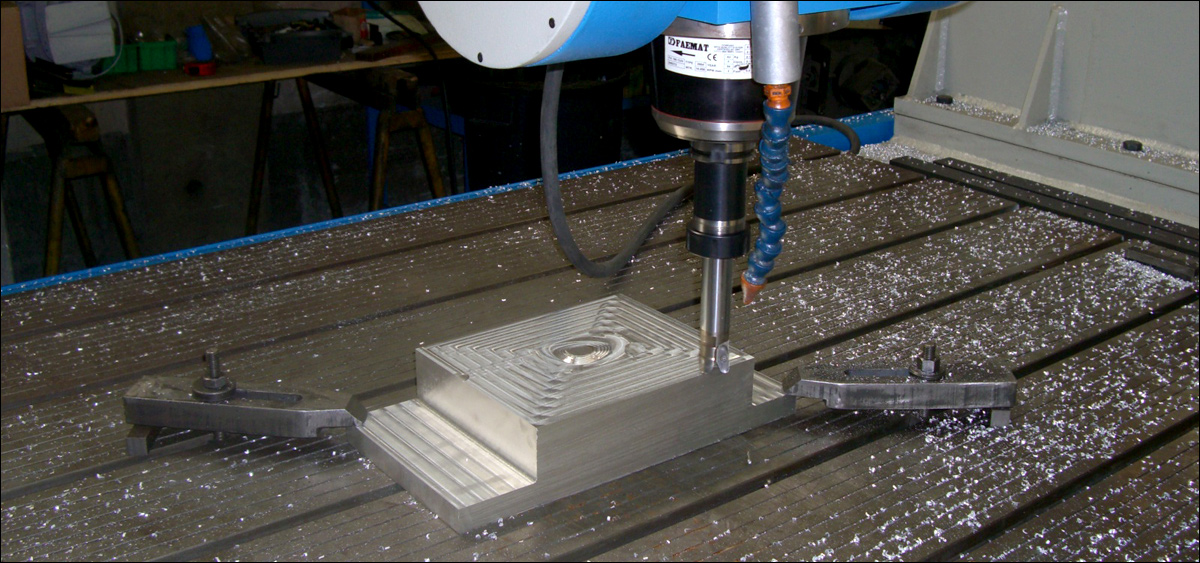

Machining of aluminum details - Trimming

The TM xxxx A milling machines fit perfectly into the processing of aluminum particulars, where you need a good material remove speed as well as a good surface quality and a high dimensional accuracy. For these reasons, our machines are built with a monolithic structure that prevents resonances and micro-vibes which could undermine the quality of the milled surface.

All our milling machines are designed individually, on the specific requests and spaces of our costumers.

All the carpentry elements of the structure are internally reinforced with ribs that guarantee an excellent rigidity to the torsion and the bending even in case of sudden changes of direction or motion reverses. Every structure before being processed is normalised in order to avoid potential future deformations.

The "A" series is equipped with two-rotating axles head, controlled by brushless servomotors with encoders mounted directly on the axles.

Precision ball screws and pre-charged nut allow the handling of all the linear axles (X,Y,Z).

High resolution encoders directly mounted on the axles or optical scales with millesimal resolution allow the tally and the position control of all the axles.

All our engines for the handling of the linear axles are high-inertia brushless.

The different kind of spindles are chosen on the basis of costumer production needs

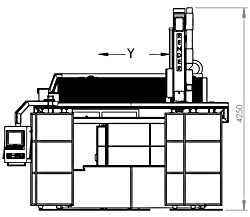

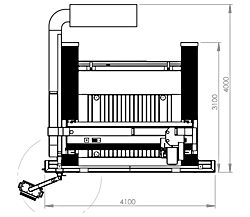

| Model | TM 1000 A | TM 2000 A | TM 3000 A |

|---|---|---|---|

| X-axis stroke in mm. | 1000 | 2000 | 3000 |

| Y-axis stroke in mm. | 1500 | 1500 | 2000 |

| Z-axis stroke in mm. | 1000 | 1500 | 1500 |

| Overall Length in mm. | 4000 | 4000 | 4000 |

| Overall Width in mm. | 3100 | 4100 | 5100 |

| Overall Height in mm. | 4000 | 5000 | 5500 |

| Angular working space controlled two-rotating head | Axis "A" +/- 120° Axis "C" +/ - 220° | ||

| Electrical Spindle | Power from 17 to 25 KW, Maximum speed 20000 rpm | ||

| Tool Fitting | HSK F63 – HSK A63 | ||