RENDER s.r.l.

RENDER s.r.l. owes its beginning in 2000, to the constant experimentation and experience of his technicians in the field of Styrofoam, resin and aluminium models. In a warehouse large approximately 4000 square metres, in the heart of Bruino industrial area, province of Turin, RENDER s.r.l. for more than 16 years, is responsible for the design, manufacturing and market of CNC 3 and 5 axis milling machines (and their spare parts) and of the related maintenance (other brands included).

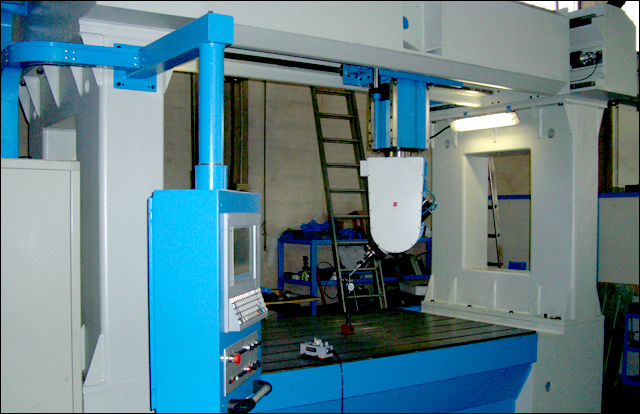

The planning of different types of milling machines, personalised according to their own purpose and to customers needs (TM7000R for automotive and nautical models,TM7000P for Styrofoam models, TM3000A for the milling and the trimming of aluminium particulars), had allowed to our company to establish itself on the national and international model shop market.

Render s.r.l. produces 3 and 5 axis high speed and medium power automated equipment for the processing of aluminium particulars and resin and Styrofoam models.

By using the most advanced technologies in design, production and quality check, our products (exported to the most developed countries) ensure performances at the upper echelons of the sector.

Render s.r.l. by the constant research, development, manufacturing, marketing and support, undertakes to ensure:

• A policy aimed to the product and the services, that takes account of all the machine's life cycle (from the assembly, to the installation, the conditions of use, the maintenance until its dismantlement) and of the related productive processes.

• That the compliance with all the laws, requirements and regulations on Environment, Health and Safety is guaranteed and kept over time.

– Planning and personalisation of equipment's lay out

– Analysis and optimisation of the production process

– Prior analysis of the processing and feasibility

– Personalised planning of every detail

– Milling technologies optimisation, in particular guaranteed by the use of high speed milling

– "Turn-key" Service, CAD-CAM and post-processing

– System integration